Ernesto Cappelletti

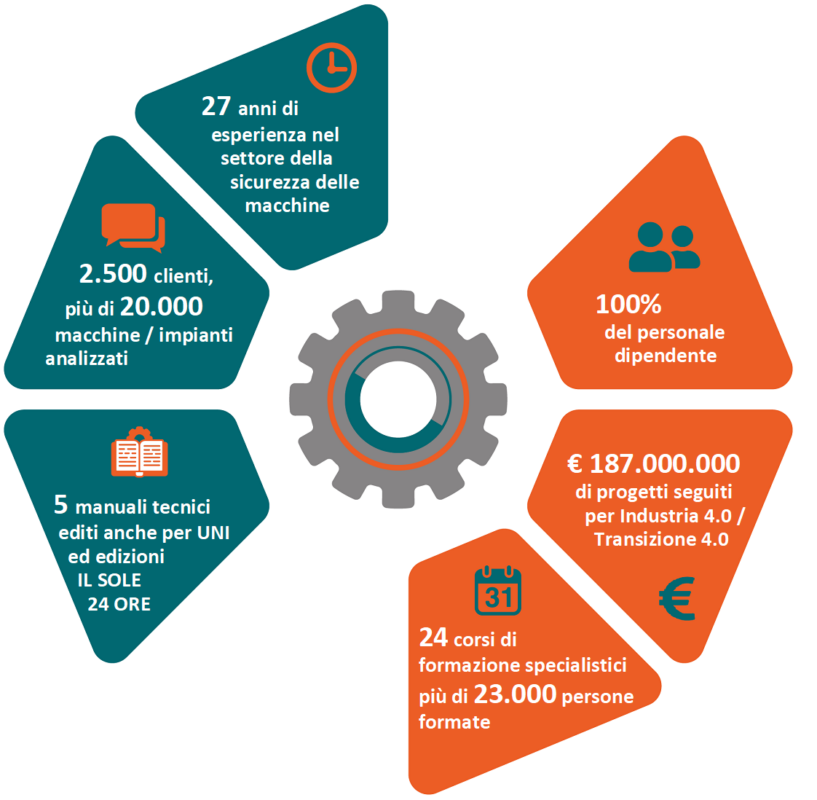

Sono un ingegnere elettronico, co-fondatore e direttore tecnico di Quadra, società che si occupa di consulenza per il supporto dei progettisti ed utilizzatori di macchine ed impianti industriali dal 1995. In questo ruolo ho assistito più di 500 clienti per la sicurezza delle macchine.

Dal 2016 sono il Rappresentante di Federmacchine in ambito UNI, relativamente agli aspetti normativi meccanici.

Dal 2019 sono iscritto negli elenchi degli Innovation Manager del Ministero dello sviluppo economico.

Sono stato membro del comitato tecnico europeo CEN TC 145 per le norme sulle macchine per gomma e materie plastiche.

Partecipo all’attività normativa UNI e ISO:

- UNI/CT 042/SC 01/GL 01, comitato tecnico “sicurezza”, sottocommissione “macchine”, gruppo di lavoro “sicurezza del macchinario”;

- comitato tecnico ISO/TC 199 “Safety of machinery”, gruppi di lavoro ISO/TC 199/WG 3 “Safety of integrated manufacturing systems”, ISO/TC 199/WG 5 “General principles for the design of machinery and risk assessment”, ISO/TC 199/WG 6 “Safety distances and ergonomic aspects”, ISO/TC 199/WG 7 “Interlocking devices”, ISO/TC 199/WG 8 “Safe control system”, ISO/TC 199/WG 11 “Permanent means of access to machinery”

- WG02 del comitato tecnico TC 44 dell’IEC. Scopo del gruppo di lavoro è l’elaborazione di una norma sulla sicurezza informatica delle macchine che si chiamerà EN 50742 con l’obbiettivo di essere armonizzata ai sensi del nuovo regolamento macchine (UE) 2023/1230, con particolare riferimento ai requisiti essenziali di sicurezza e di tutela della salute 1.1.9 e 1.2.1.

Partecipo anche all’attività normativa CEI e IEC:

- comitato tecnico CT 44 “Equipaggiamento elettrico delle macchine industriali”,

- comitato tecnico IEC TC 44X “Safety of machinery: electrotechnical aspects” e gruppo di lavoro IEC TC 44X/WG 02 “Protection against corruption (including safety-related cybersecurity aspects)”,

- comitato tecnico CT 121 “Apparecchiature e quadri protetti per bassa tensione”, sottocomitato SC121B “Quadri protetti per bassa tensione”,

Ho partecipato alla redazione delle seguenti linee guida:

- per Federmacchine: “La gestione degli insiemi di macchine: aspetti tecnici, operativi e legali”.

- per Assomac: “Gli interventi da remoto: aspetti legali, tecnici e di sicurezza”.

Ho seguito l’iter di definizione del testo del nuovo Regolamento macchine, fornendo osservazioni, per conto di alcune associazioni aderenti a Confindustria.

Sono coordinatore del gruppo di lavoro UNI incaricato di scrivere la nuova UNI/PdR sulla figura dello specialista in sicurezza delle macchine nell’ambito delle attività professionali non regolamentate.

Sono stato per otto anni ispettore TÜV PS Italia per macchine in allegato IV della direttiva macchine, con curriculum approvato dal Ministero dello Sviluppo Economico; dal 2014 al 2021 sono stato ispettore per macchine TÜV Nord.

Sono consulente tecnico della Procura di Treviso e della Procura di Ascoli Piceno e dell’ASL n. 3 Alto Friuli e docente nei corsi sulla sicurezza delle macchine presso UNI, ACIMAC, UCIMA, AMAPLAST, ACIMIT, APA Confartigianato, Confindustria Modena, Reggio Emilia, Bergamo, Varese, Lecco e Sondrio, Firenze, Toscana Sud.

Ho scritto, per Il Sole 24 Ore, il testo base sulla Direttiva Macchine e, sempre per Il Sole 24 Ore, l’unico libro esistente in Italia sull’applicazione della norma UNI EN ISO 13849-1.

Nel 2021 ho scritto il libro “Come applicare la direttiva macchine 2006/42/CE e le norme di riferimento”.

Nel 2023 ho scritto assieme a Chiara Cappelletti il libro: "il Regolamento Macchine (UE) 2023/1230 - Guida all'applicazione pratica

Da sempre ogni competenza tecnica acquisita è servita a fare crescere il Know How di Quadra ed il Team di risorse che negli anni abbiamo selezionato, formato e che quotidianamente opera insieme a me per garantire il migliore sevizio possibile ai nostri clienti.

Elena Bottura

Ho studiato fisica nucleare presso l’Università di Padova, ma – subito dopo la laurea – ho abbandonato la fisica per il marketing.

Infatti, la mia prima esperienza lavorativa è stata presso ST Microelectronics, come marketing manager per dispositivi a logica programmabile, successivamente account manager per CANON e HP. In ST Microelectronics ho incontrato per la prima volta mio marito, Ernesto Cappelletti.

Nel 1995, ho fondato, con Ernesto Cappelletti, la società Quadra Srl e nel 1996 ho dato le dimissioni da ST e iniziato la mia carriera imprenditoriale.

Ernesto, prima che socio, è anche padre delle mie due figlie, Chiara, Ingegnere Meccanico, ed Elisa, Ingegnere Gestionale, tutte e due laureate al Politecnico di Milano.

Inizialmente mi sono occupata della parte commerciale ed amministrativa, poi, già un anno dopo, con i primi due collaboratori, ho iniziato a seguire anche la parte organizzativa.

Nel tempo sono cresciuta anche dal punto di vista tecnico rendendomi indipendente nella prima fase di analisi dei fabbisogni del cliente.

Nel periodo di pubblicazione della Direttiva Macchine sono arrivati i primi contatti con costruttori di macchine in fiera; poi con Apa Confartigianato, che ci chiese di avere un supporto per gli associati su queste tematiche particolari che erano quasi sconosciute al tempo.

Gestisco quindi da sempre tutta la parte commerciale e contrattuale.

Negli anni ho deciso la strategia di marketing, selezionando i servizi sui quali focalizzarci e cercando di conquistare clienti sempre più importanti, sostenuta dalla credenza che si cresca mettendosi alla prova in problemi sempre nuovi e più complessi.

Abbiamo sempre pensato che fosse più importante, e di soddisfazione per noi, risolvere un problema complicato di un cliente, ed acquisire Know How, che non aumentare il fatturato con lavori semplici e ripetitivi.

Nonostante, o forse proprio per questo, il fatturato è sempre cresciuto, come anche il numero dei clienti e le loro esigenze.

Ho pianificato e gestito gli investimenti nelle varie sedi aziendali e questo, insieme all’impegno per ottenere gli accreditamenti regionali, ci ha molto aiutato nella crescita del fatturato.

Sono responsabile del Centro di Formazione ed anche del Centro di ricerca e possiedo la qualifica di RSPP per gli Ateco 4,6,9.

Dal 2019 sono iscritta negli elenchi degli Innovation Manager del Ministero dello sviluppo economico.

Oltre a questo mi occupo di tutte le attività promozionali di Quadra: seminari tecnici gratuiti, fiere, attività sui social e promo.

Il Team

Il nostro team tecnico è costituito da 17 tecnici laureati e altamente qualificati con un’età media che non supera i 35 anni. Le competenze e le esperienze specifiche di ciascun consulente costituiscono il punto di forza di una squadra che opera con sinergia e ci consente di individuare soluzioni valide ed efficaci per i clienti.

Fanno parte del nostro team tecnico ingegneri

- meccanici

- della sicurezza

- chimici

- elettronici

- aerospaziali

- biomedici

- ambientali

- informatici

- automazione

- materiali

Tutti nostri tecnici sono personale interno dipendente, questo ci permette di avere metodologie uniformi e condivise, un continuo scambio di informazioni e un aggiornamento costante e reciproco.

La qualifica del nuovo personale prevede oltre alla formazione interna e/o esterna, affiancamenti con consulenti senior per almeno 12 mesi.

All’interno della direzione tecnica sono state individuate 4 figure tecniche di riferimento per le seguenti tematiche principali:

- Aspetti legali della Marcatura CE, sicurezza elettrica

- Circuiti di comando con funzioni di sicurezza, valutazione dei rischi

- Sistemi di combustione (forni), Software con funzioni di sicurezza, equipaggiamenti pneumatici ed idraulici, Atex

- Norme UL , CSA, NFPA, ANSI, AS.

I referenti delle tematiche hanno la responsabilità, una volta stabilito le specifiche del servizio, di verificare l’uniformità di erogazione dei relativi servizi, anche attraverso verifiche a campione sui lavori effettuati dai diversi consulenti.

Il personale qualificato per la formazione sulla sicurezza delle macchine ha almeno 5 anni di esperienza nel settore e tutti i formatori esercitano anche l’attività di consulenza, al fine di garantire il continuo aggiornamento sul campo.

Altre 6 persone seguono le attività commerciali di coordinamento ed amministrazione della società e sono:

Elena Camporiondo: amministrazione

Giulia Brambati: assistente direzione tecnica e fornitori

Elena Bottura: direzione marketing e commerciale

Roberto Gambogi: vendite

Alessandro Cavallotti: vendite

Gabriele Villa: responsabile della pianificazione

Manteniamo un ambiente costruttivo e sereno.