Siamo il punto

di riferimento per la

Sicurezza delle Macchine Industriali

Risolviamo problemi tramite

dal 1995 ci occupiamo solo di macchine industriali

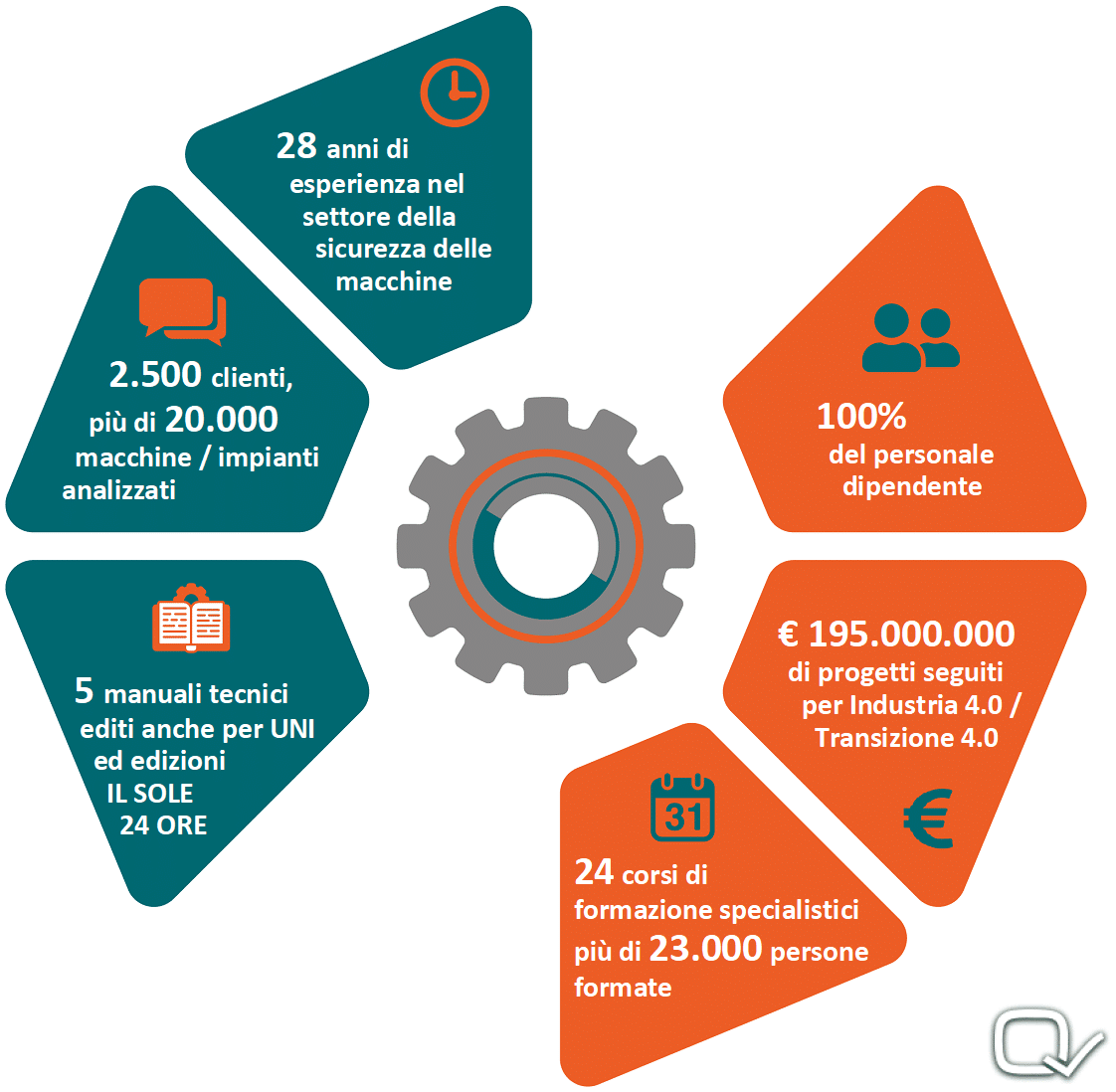

Negli ultimi 28 anni abbiamo imparato ad analizzare le macchine industriali, rispetto ai requisiti delle normative applicabili, per aiutare le piccole e grandi aziende a garantire la sicurezza dei macchinari.

Oggi Quadra conta più di 20 consulenti ed affianchiamo progettisti e RSPP per la marcatura CE delle macchine nuove e per assicurare la sicurezza delle macchine usate.

Con test, calcoli e verifiche assicuriamo la conformità delle macchine alle norme, direttive e regolamenti europei ed extra europei (UL, NR12). Dal 2017 verifichiamo le macchine interconnesse secondo INDUSTRIA 4.0 e TRANSIZIONE 4.0 per l'ottenimento del credito di imposta 4.0.

La nostra storia nasce con l’ing. Ernesto Cappelletti, ora Rappresentante Federmacchine in UNI per gli aspetti normativi meccanici. Il nostro punto di forza è l’esperienza, grazie alla quale siamo in grado di affrontare anche le sfide tecniche più difficili.

Dal 2000 formiamo i partecipanti ai corsi di UNI, e dal 2015 siamo Ente Formativo Accreditato da Regione Lombardia (Operatore n. 822).

Crediamo che per operare nel campo della sicurezza delle macchine servano esperienza e competenza. Per questo investiamo nello studio delle norme, nello sviluppo e nella standardizzazione dei metodi. Non ci occupiamo della marcatura CE di altri prodotti, come giocattoli o dispositivi medici, facciamo una COSA SOLA e bene.

Consideriamo il nostro team importantissimo, infatti lavoriamo esclusivamente con personale dipendente fin dalla fondazione. Se vuoi sapere di più sulla nostra storia continua a leggere qui.

l'offerta formativa più completa sulla direttiva macchine

siamo principalmente consulenti non insegnanti

Abbiamo iniziato aiutando i clienti sulle macchine in officina e lavoriamo ancora in questo modo: non siamo consulenti da giacca e cravatta.

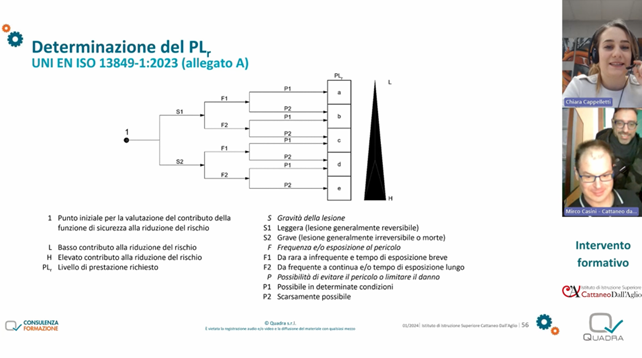

I nostri docenti hanno almeno 2 anni di esperienza sul campo in attività di consulenza; infatti, affinché i nostri tecnici possano trasmettere efficacemente le conoscenze, devono avere praticato in prima persona gli argomenti trattati dai corsi.

Questo significa che il nostro docente quando spiega come deve essere verificata una funzione di sicurezza, trasferisce un metodo che lui stesso applica tutti i giorni.

Proprio per questo possiamo formarti al meglio lavorando sulla tua applicazione in modalità affiancamento.

siamo consulenti che fanno e non solo che consigliano

Alcuni consulenti pensano che loro attività consista solo nel consigliare il cliente, noi pensiamo invece che il consulente debba anche fare, ovvero effettuare verifiche, prove e calcoli, scrivere documenti, prendere posizioni e scrivere pareri, anche su questioni controverse.

Siamo consulenti che vogliono stare al fianco del cliente ed assumersi responsabilità.

Scopri la nostra Consulenza

I nostri Corsi di Formazione

Scopri le date dei corsi interaziendali

(presso le nostre aule e da remoto)

Scarica il Catalogo corsi in house

ti mettiamo a disposizione articoli ed aggiornamenti gratuiti

Nel nostro BLOG, e canale YOUTUBE, sono disponibili moltissimi documenti, video didattici, pareri tecnici gratuiti, parti di corsi ed articoli estratti dai nostri libri pubblicati per IL SOLE 24 ORE.

Nella sezione NEWS del sito troverai inoltre tutte le novità normative del settore, quasi in tempo reale, perché facciamo parte di molti comitati tecnici UNI, EN, ISO, CEI e gruppi di lavoro Federmacchine con INAIL ed ATS Lombarde.

Sono tutti contenuti tecnici di valore, non commerciali, perché crediamo che la sicurezza delle macchine sia una cosa molto seria.

Transizione 4.0, Industria 4.0, Credito d’imposta 2023-2024-2025

Vuoi avere maggiori informazioni su Transizione 4.0? In questo articolo abbiamo raccolto le principali domande e risposte su Transizione 4.0,ovvero il credito di imposta valido per il triennio 2023-2025 e sui […]

Webinar – I requisiti di sicurezza dei carrelli industriali senza guidatore a bordo (AGV)

WEBINAR – I requisiti di sicurezza dei carrelli industriali senza guidatore a bordo (AGV) Il 12 giugno 2024 è in programma dalle ore 10:30 un webinar con Tritecnica S.p.A. che […]

Cybersafety nelle Macchine: avviata la nuova prassi di Riferimento

Riportiamo di seguito una notizia da UNI perché parteciperemo al tavolo di lavoro sulla cybersecurity applicata alle macchine tramite il nostro direttore tecnico, Ing. Ernesto Cappelletti . “Senza dubbio, il digitale […]

Webinar e seminari 2024

Quadra S.r.l, con i due Tecnici Ernesto Cappelletti e Chiara Capelletti, saranno presenti a diversi Webinar ed eventi sul Nuovo Regolamento Macchine 2024 e sulla sicurezza dei macchinari organizzati con […]

Quadra per la scuola: interventi gratuiti per gli Istituti Tecnici Superiori

Nel 2022 abbiamo dato vita ad un progetto di cui abbiamo capito l’importanza nel corso della pandemia, ovvero la formazione degli studenti delle scuole tecniche italiane. Quadra è una società […]

Webinar e seminari gratuiti 2023

Quadra S.r.l, con i due Tecnici Ernesto Cappelletti e Chiara Capelletti, saranno presenti a diversi Webinar ed eventi sul Nuovo Regolamento Macchine 2023 organizzati con molti partner di Quadra S.r.l. […]

Vuoi rimanere in contatto con noi?

Non conoscere le leggi e le norme, che regolamentano la fabbricazione e l’uso in sicurezza dei macchinari, può comportare rischi e costi molto alti, iscriversi alla nostra newsletter, per rimanere aggiornati, è gratis

"*" indica i campi obbligatori